the production of biologic drugs such as monoclonal antibodies, vaccines, and enzymes has traditionally been a complex, time-consuming, and costly process. With the rise of smart technologies, this landscape is rapidly changing. Smart biomanufacturing integrates advanced digital tools and artificial intelligence to streamline production, improve product quality, and reduce costs. As global demand for biologics continues to surge, adopting AI-driven biomanufacturing solutions is becoming essential for pharmaceutical companies aiming to innovate and remain competitive.

What is AI and How Does It Apply to Biomanufacturing?

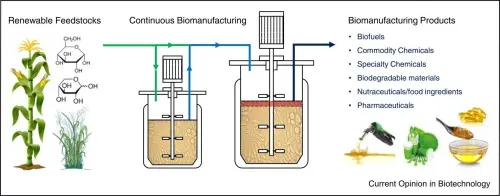

Biomanufacturing involves the production of complex biologic products such as monoclonal antibodies, and recombinant proteins using living cells. This process requires careful control and optimization of multiple factors, including cell culture conditions, nutrient supply, and purification steps, to ensure high product quality and yield. Throughout production, vast amounts of data are generated from bioreactor parameters and environmental conditions to sensor readings and quality control results. Effectively managing and interpreting this data is critical to maintaining process consistency and meeting stringent regulatory standards. By leveraging advanced data analytics, manufacturers can better understand how subtle changes in the production environment impact cell growth and product formation. This deeper insight enables proactive adjustments to minimize variability, optimize yields, and enhance reproducibility, ultimately ensuring that biologics are produced efficiently, safely, and at scale.

Key AI Technologies Used in Biologic Production

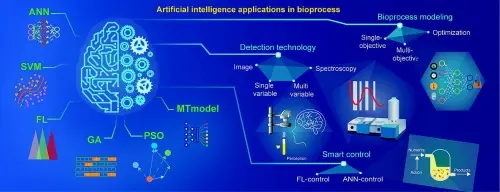

The application of AI in biomanufacturing leverages several key technologies. Machine learning algorithms process historical and real-time data to generate predictive models that guide process optimization. For instance, supervised learning models can predict cell viability based on input parameters like temperature and pH. Computer vision systems, equipped with deep learning, enable automated inspection of cell cultures and identification of contamination or morphological changes without human bias. Robotics integrated with AI perform repetitive tasks such as pipetting, sampling, and media exchanges with exceptional precision and consistency. Additionally, natural language processing (NLP) helps analyze scientific literature and production reports to extract actionable insights. Predictive maintenance systems use AI to forecast equipment failures before they occur, minimizing costly downtime and ensuring uninterrupted production.

Improving Process Optimization and Efficiency with AI

Biologic production involves intricate processes such as cell culture fermentation, downstream purification, and formulation. Each step can be influenced by numerous variables nutrient composition, temperature, agitation speed, and more that impact yield and quality. Traditionally, optimizing these parameters required extensive laboratory experiments, which are time-consuming and expensive. AI transforms this by using predictive models to simulate how changes affect outcomes, enabling rapid in silico optimization. For example, reinforcement learning algorithms can iteratively adjust bioreactor conditions to maximize product yield while minimizing impurities. This leads to more efficient processes that reduce production time and material waste. Furthermore, AI-driven adaptive control systems can respond in real time to fluctuations during production, maintaining optimal conditions and ensuring batch-to-batch consistency.

Artificial Intelligence Technologies in Bioprocess: Opportunities and Challenges

This review examines how artificial intelligence (AI), particularly machine learning (ML), is advancing bioprocess optimization by predicting critical process parameters like temperature, pH, and nutrient levels that impact cell growth and product quality. It highlights AI-driven control strategies that enable real-time process adjustments, reducing variability and accelerating development. The review also discusses integrating AI with genetic engineering models (GEMs) to better understand cellular responses and with computational fluid dynamics (CFD) to optimize bioreactor conditions. While AI offers great potential to improve efficiency and consistency in biomanufacturing, challenges remain around data quality, system integration, and regulatory compliance.